| Highest Standards of Precision and Quality |

| Our team of experts has extensive experience in the industry and utilizes the latest technology and strict quality control measures to ensure that your parts are made to the highest standards of precision and quality. |

|

|

| Our brilliant CNC prototyping services are making us a great one-stop-solution for your superior designs. Contact our professional team to get a free quote and to talk about which process is the appropriate one for your next project. Our CNC prototyping services offer a good solution for engineers and designers working at R&D department. |

We have highly skilled machinist who provide premium quality CNC machined parts quickly and accurately. We are always pleased to help you to meet your needs in the best manner. Our automated cutting tools take away material from a block of pre-existing part as per your design needs. We make use of advanced software for controlling the gears according to the directives of your CAD drawing file.

Our team of qualified machinists programs the tool to optimize cutting time, final tolerance and surface finish to satisfy your design specifications. We use prototype machining not only to create finished products but also to craft mold equipment which may later be utilized for pressure die casting of plastic injection molding.

---Our CNC machining services offer a plenty of benefits and it is worth for your money.

|

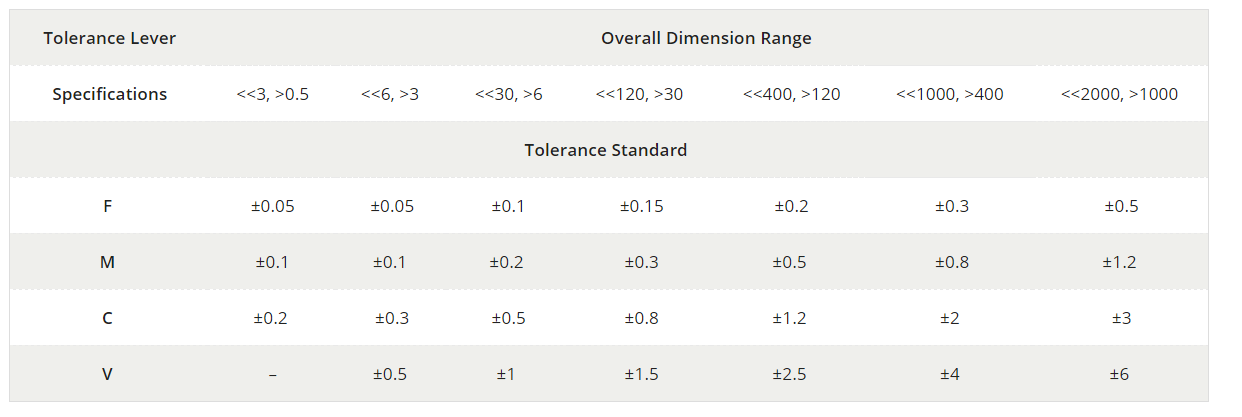

| Our general tolerance is ISO DIN 2768f for metal parts and 2768m for plastic parts. If you required finer tolerances, our precision CNC machining service is the solution. Our experienced engineers will work with you to solve the technical challenges before production, make sure your parts are designed for CNC manufacture. We aim to please clients with excellent results. |

| CNC Machining Materials |

Aluminum: AL6061-T6,AL6063,AL6082,AL7075-T6,AL5052, etc.

Steel: SUS301, SUS304, SUS303,SU316L,SUS440C,S355ML, S420ML, P20,SKD11, SKD61,SKH9, SKH51,S45C, etc.Other Metal: Titanium, Brass, Copper, Magnesium,Nickel etc.

Plastic: ABS,PP,PC, Ny/on,PMMA, PEEK, Nylon+ 30%GF, Acetal (POM), PE,UHMWPE, PET, PTFE (Teflon), etc. |

| CNC Machining Finishing In First Part |

*Standard Surface/As manufactured

*Anodizing

*Painting

*Plating

*Electropolishing

*Chrome-plating

*Polishing

*Texturing

*Custom

As machined (around Ra3.2um), Smooth (around Ra1.6um),Polishing (around Ra0.8um), Mirror Polishing (aroundRa0.5yum) 1,Capable of machining parts with very tight tolerance and very complex geometry.

|

Capabilities

| CNC Machining | Plastic injection Molding |

| 3D Printing | Aluminum Extrusion |

| Sheet Metal | Die Cutting |

| Vacuum Casting | Thermoforming Mould |

| Low Volume Manufacturing | Parts Finishing |

Contact Us

| Phone : +86 750 34 678 00 |

| Mobile :+86 750 34 678 00 |

| E-mail :sales@qbprecision.com |